I made a post over at the popular Arduino forum on a topic where someone was inquiring about available enclosures. The community tends to respond “just 3D print one” but that’s a mistake in my opinion.

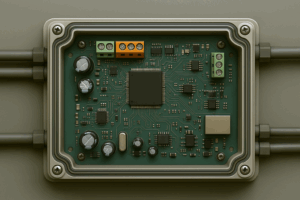

3D printing, while useful, seems pointless to me unless you’re looking for something not available off the shelf. Even then, the 3D print falls short if you need a transparent cover, or a NEMA4X /IP66 (washdown-proof) rating, or any number of other structural properties. That off the shelf $20 polycarbonate case has a lot of engineering time put into it and provides a huge amount of convenience.

As far as laser cut enclosures are concerned, I’ve yet to find one that doesn’t look completely ugly like something a 6 year-old put together for a craft class.

Seriously, burnt wood edges is not a professional look! I have seen professional enclosures for large machines made out of wood and particle board and you’d never know what the material was. When designed by an engineer who knows what he’s doing, wood can be a fantastic material.

The amateurish laser-cut “snap together jigsaw cases” all look like crap in my opinion. And that’s a pity, because you can do some great stuff with a laser cutter. It’s just that the community has apparently decided to embrace the lowest common denominator design quality.

My gotos for great cases are Polycase & Bud for plastic wall and desk mount enclosures. Polycase is great for getting your enclosures custom modified (cutouts, slots, custom printing, etc.) at reasonable prices. I also like Hammond for metal enclosures (although Bud has some nice aluminum cast boxes). Serpac or OPC for handheld/belt mount types. Altech for industrial enclosures with electrical knockouts (although Polycase is now carrying those also).

A few links:

Polycase https://www.polycase.com/

Bud https://www.budind.com/plastic_boxes.php

Small Hammond enclosures. I like these for Arduino Nano since they fit nicely and the 1551 enclosure comes in many versions http://www.hammondmfg.com/dwg9.htm

You can find these and many, many more enclosures for sale at my favorite electronics distributor, Digi-Key. Note that Amazon also carries many electronics enclosures, but I haven’t found enough of a price difference to offset not having reliable datasheets.

If you’d like to subscribe to this blog, please click here.